Our customers may have a great product idea, but they may not have the space, or the equipment or the technical expertise to make samples. Here is where we come in.

Following an example how this typically works or the process gets started:

- the customer may provide an optional “None-Disclosure Agreement” (NDA), which we sign

- then, the product idea will be discussed and to which extend we may be of help

- then we provide a quotation with terms & conditions

- then the customer accepts the quotation

- then the sample making begins

After the sample making, the customer can decide to outsource the manufacturing through us or can decide to setup his own manufacturing. In the latter, we can help, as well.

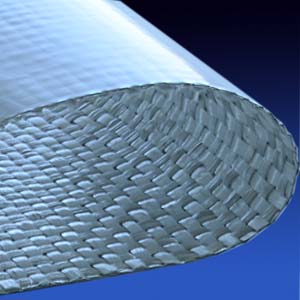

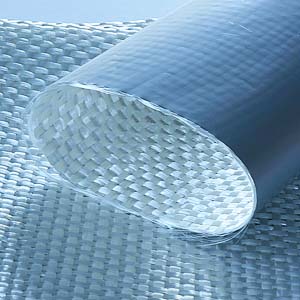

WOVEN BASALT – S-Glass Hybrid

When creating hybrid fabrics, based on two or more different fibers, you can engineer a fabric very precisely according to its particular technical requirements. E.g. you may need more tensile strength in one direction (using S-Glass) and regular E-Glass in a 90 degree angle, Hybrids optimize the product at the lowest possible cost.

In this case, we used S-Glass and Basalt fibers. Both have mechanical properties which are very closely related in tensile strength and temperature.

As an independent weaver, we can have access to fibers from various sources.

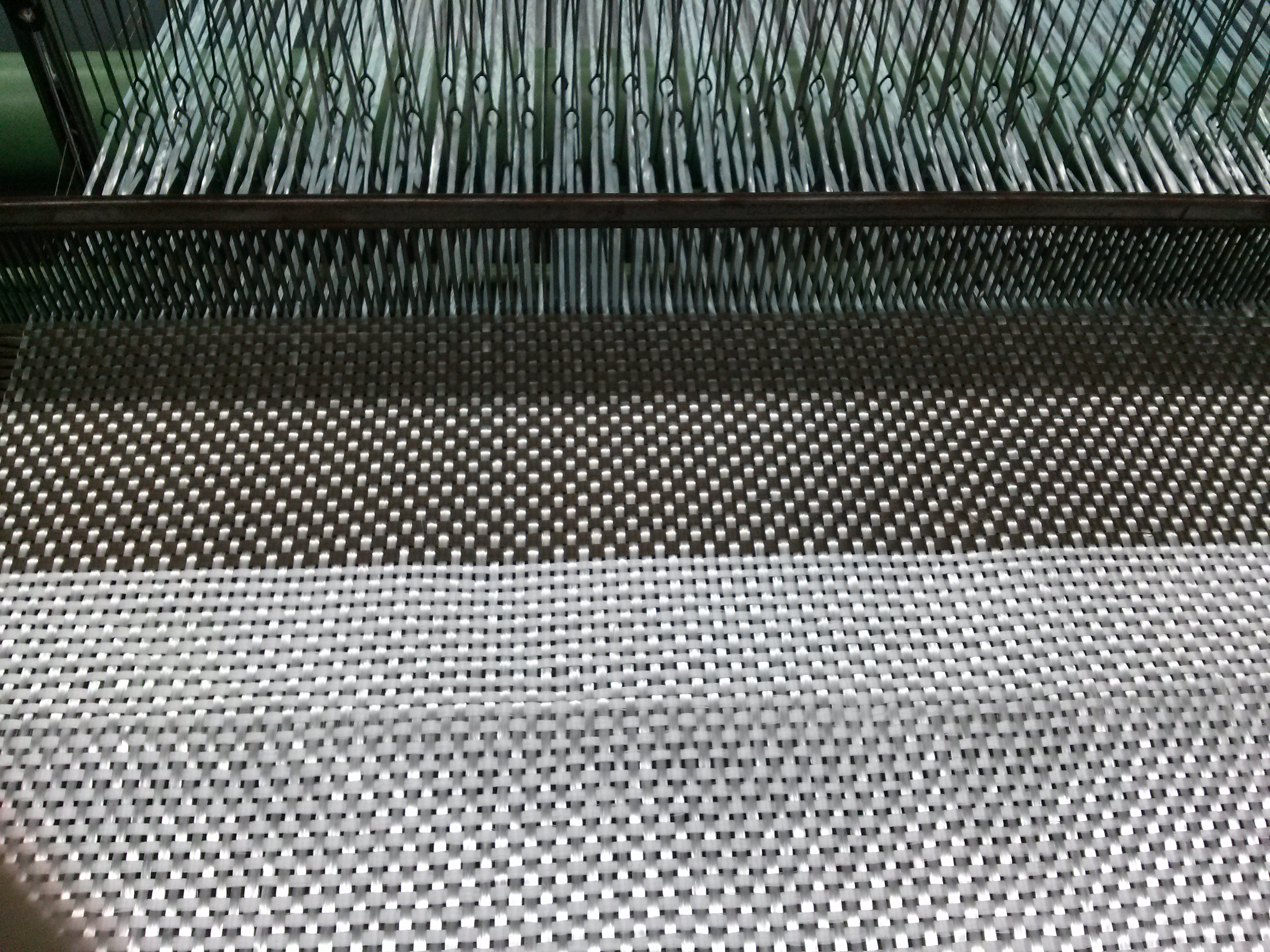

WOVEN BASALT LENO – OPEN MESH

Above is a 100% woven Basalt open mesh with zero foreign products inside. It makes it a true clean & green product.

Since Basalt fibers are basically rock molten and then formed into a fiber, it is considered to be a “green” product and will not require any special landfill.

Basalt fibers are becoming a strong trend in Europe, due to their “green”, environmentally friendly properties.

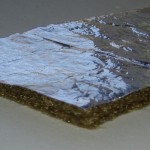

LAMINATED PRODUCTS:

All product ideas will go through a sample making process. Above are a few examples for sample making we underwent.

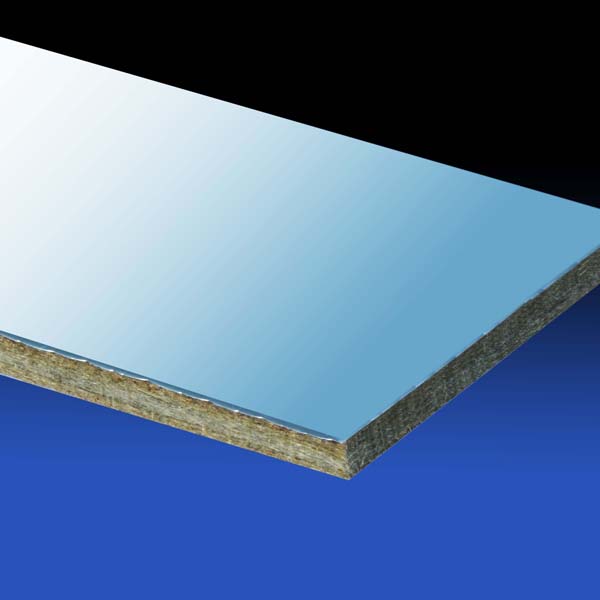

In this particular case we laminated a heavy 24 oz/ syd woven roving fabric to an aluminum foil. Our “Sample Laminator” is capable of laminating 38″ wide.

We also laminated the foil to a Basalt Needlemat.

Our laminating machine relies on heated rollers to press the media onto the fabric. The heat will activate the glue and allows for the media to stick to the fabric.

Laminations are value added process which upgrade the substrate. The aluminum foil in this example can function as a heat barrier or chemical barrier.

Other media than aluminum can be laminated as well. Multilayering a fabric increases the physical properties of the final product; insulation values, strength, wear & tear resistance and many more. They can also be machined (cut into similar shapes as shown below with the “CNC-Machined Basalt Insulation Boards”.

There are many media available, as well as many different types of substrates which can be woven in our facility.

CNC-MACHINED BASALT INSULATION BOARDS:

In the above example, we outsourced the machining of these samples.

Machining boards such as these can be very useful in high temperature insulation applications. it could be a door seal or many “donuts” stacked up on a pipe would make a thick pipe insulation.

In cases like the above, we would make thermal conductivity calculations, in order to determine the minimum thickness for optimal thermal insulation.

SEWN & GROMMETED PRODUCTS:

Above a few examples of value added services we are involved in.