The reason to choose us for contract chopping can be multifold:

- A fiber chopping company may operate at capacity and is looking to outsource some of their existing orders. Or they may not have the right type of chopping technique, to cut certain fibers.

- A distributor may look to expand their product offering or to be able to draw from a more local source, in order to reduce cost in logistics.

- An engineer may look into developing a new product, tailored to his particular industry.

- A sales person may have a great idea of a product he/she thinks can be marketed.

We are passionate about our industry and regardless the size of the project, we would be thrilled to help!

OUR CHOPPING CAPABILITIES:

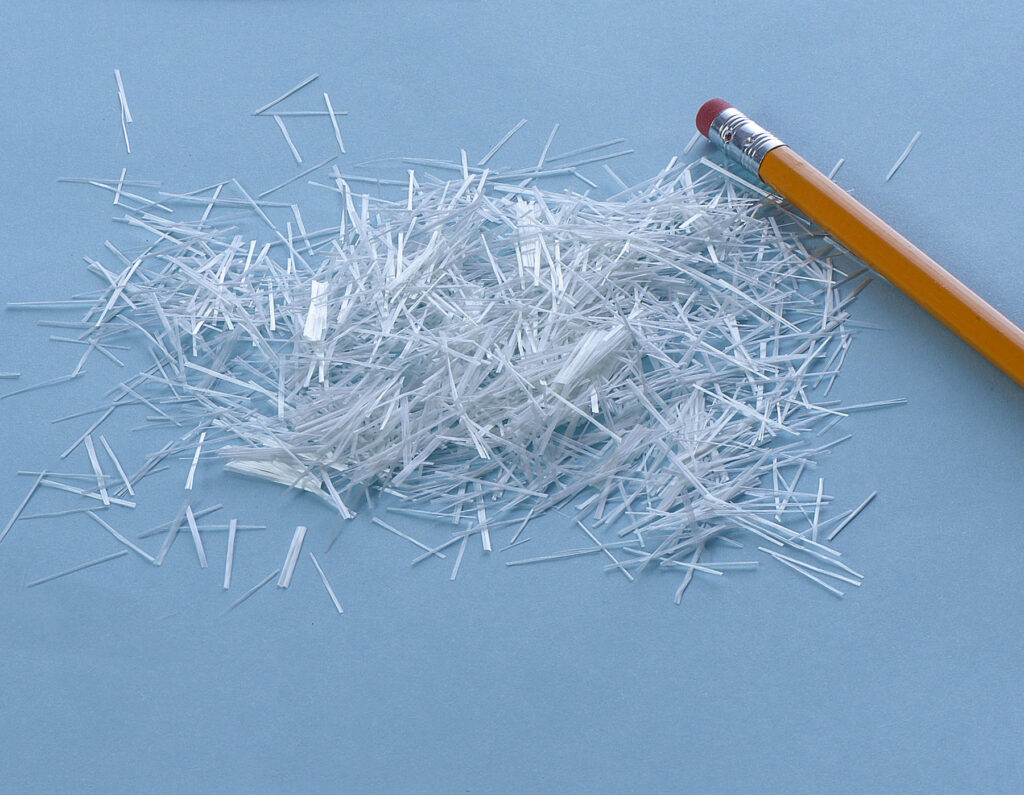

By modifying our machines, we can chop almost any technical fiber, such as glass, carbon, basalt, etc. Especially fibers with a crystalline structure are suitable for our machines.

Sometimes, blending various fibers may add to optimizing the final product. Our machines thread multiple fibers at the same time and we can run a certain combination, yielding in very exact results.

Following are typical fiber lengths: 1/4″, 1/2″, 3/4″, 1″, others can be discussed.

After the processing, there will be discussions about packaging; here too, we can customize according to customer specification, being it bulk boxes or small bags.

For reading more about chopping: https://allendalefibertech.com/about-chopping/

THE SAMPLE-MAKING PROCESS:

Following an example how this typically works or the process gets started:

- The customer may provide an optional “None-Disclosure Agreement” (NDA), which we sign

- then, the product idea will be discussed and to which extend we may be of help

- then we provide a quotation with terms & conditions

- then the customer accepts the quotation

- then the sample-making begins

After the sample-making, the customer can decide to outsource the manufacturing through us or can decide to setup his own manufacturing. In the latter, we can help, as well.