Following explanation shall be written in layman’s terms and simply serve the purpose of understanding the basic concept. It is, by all means, incomplete.

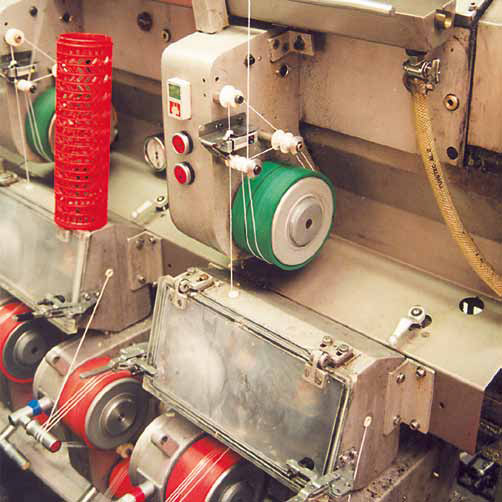

There is air and water texturizing. We shall focus on dry air texturizing.

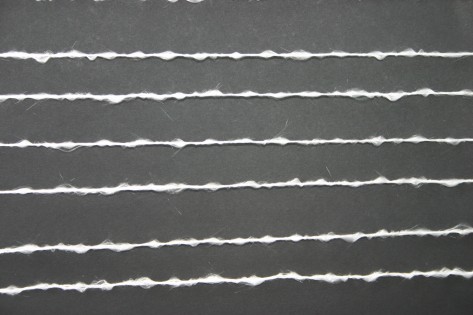

During the air texturizing process, one or more strands of filament fibers will be conducted through an air nuzzle. The air pushed through the nuzzle will cause the single filaments to entangle, thus locking the strands together; but also making the fiber bulkier.

The bulkiness is desired for various reasons. It could be required when weaving wallpaper from glass, the the bulky fiber serves a decorating purpose. In thermal applications, such as welding blankets, the bulky fiber stores more air and increases the insulation values of a fabric.

In our facility, we will be able to weave e.g. texturized glass or texturized basalt; most likely, it would be woven from a creel.

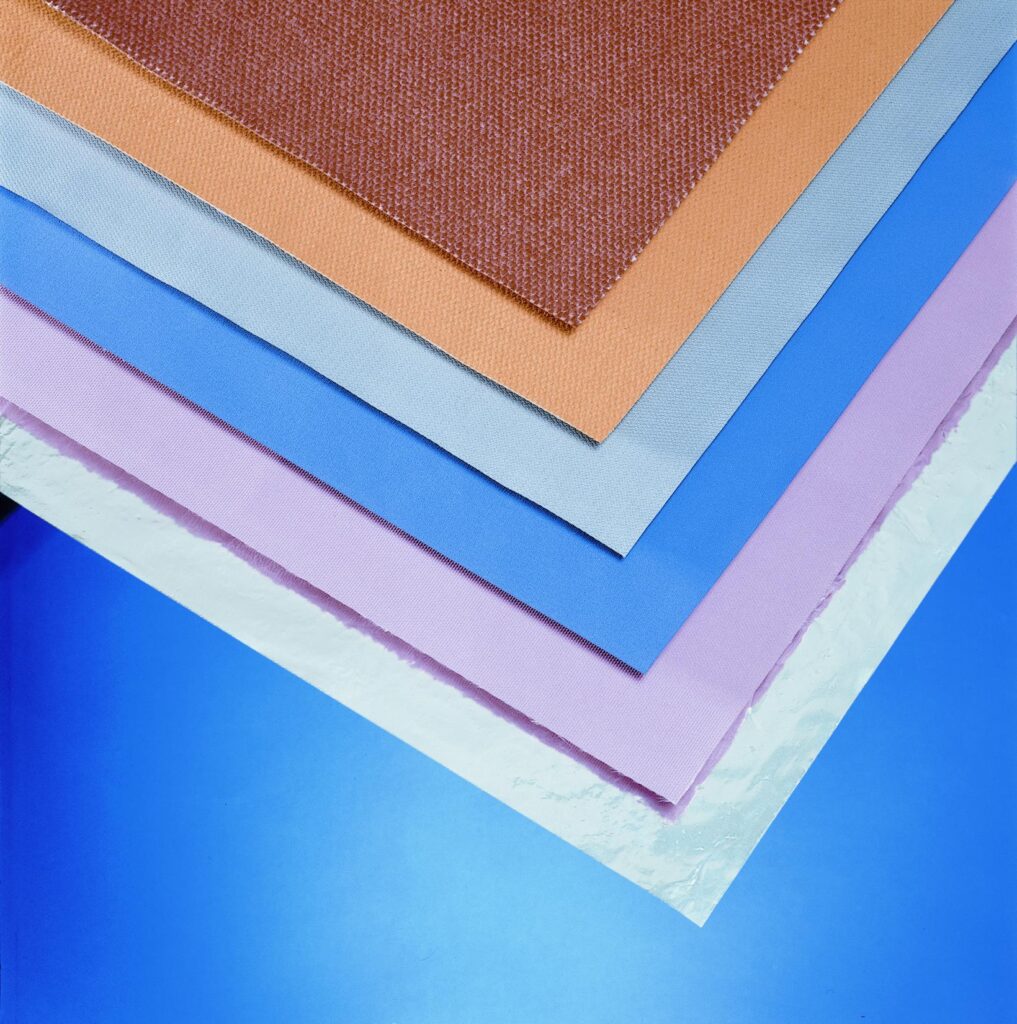

A fabric from texturized fibers can be coated, laminated or impregnated with a media which help enhance its properties.